Introduction to Pyrolysis and its Benefits

In a world increasingly burdened by waste, innovative solutions are emerging to tackle the crisis. One such groundbreaking technology is the pyrolysis machine, which transforms discarded materials into valuable energy. Imagine turning plastic bottles and rubber tires into fuel! This process not only reduces landfill waste but also harnesses energy that can power homes and businesses.

The benefits of pyrolysis extend beyond mere waste management; they touch on sustainability, economic viability, and environmental health. Curious about how this remarkable technology works? Let’s dive deeper into the science behind pyrolysis and discover its potential in revolutionizing our approach to waste disposal and energy production.

The Science Behind Pyrolysis: Breaking Down the Process

Pyrolysis is a thermal decomposition process occurring in the absence of oxygen. It transforms organic materials into valuable resources through controlled heating.

As waste material is fed into the pyrolysis machine, it gradually heats up to high temperatures, typically ranging from 300°C to 900°C. This heat breaks down complex molecules into simpler compounds.

The breakdown generates three primary products: gas, oil, and char. Each product has distinct uses—gas can be used for energy generation while oil can serve as biofuel. Char remains as a solid residue that holds potential for carbon sequestration or soil enhancement.

The efficiency of this process relies on precise temperature control and residence times within the reactor chamber. Properly managed conditions ensure maximum resource recovery and minimal emissions.

This fascinating interplay of chemistry turns discarded materials into viable energy sources while addressing waste management challenges.

Types of Waste that can be Converted into Energy using a Pyrolysis Machine

Pyrolysis machines can transform various types of waste into valuable energy sources. One of the most common materials processed is plastic waste. This includes everything from single-use bags to containers that would otherwise end up in landfills.

Organic waste, such as agricultural residues and food scraps, also fits well within this technology. These materials decompose naturally but can produce more energy when subjected to pyrolysis.

Rubber products, particularly used tireus, represent another significant category. Pyrolysis effectively extracts oil and gas from these tough materials.

Moreover, biomass like wood chips and paper can be efficiently converted too. Such processes not only reduce landfill loads but also create sustainable energy solutions.

Each type of waste contributes uniquely to the overall efficiency of a pyrolysis machine, showcasing its versatility in managing diverse refuse streams while generating clean energy.

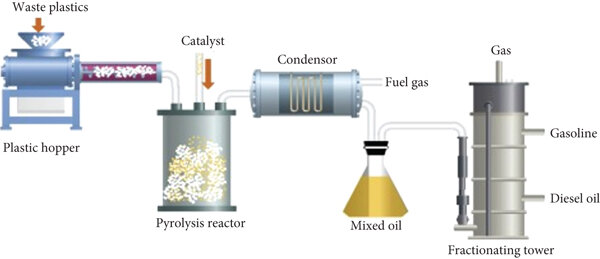

The Working Mechanism of a Pyrolysis Machine

A pyrolysis machine operates through a fascinating and efficient mechanism. It begins by heating organic materials in an oxygen-free environment. This absence of oxygen prevents combustion, allowing thermal decomposition to take place.

As the temperature rises—typically between 300°C to 900°C—the waste breaks down into various components. Gases, oils, and char are produced during this process. The gases generated can be further refined for energy production.

The solid residue left behind is biochar, which has applications in agriculture and carbon sequestration. Each component adds value in different ways.

Advanced automation equipment controls the entire operation, ensuring optimal temperatures and pressures are maintained throughout the process. With precision monitoring systems, it minimizes human intervention while maximizing output efficiency. This technology not only transforms waste but also harnesses renewable energy effectively.

Applications of Pyrolysis Technology and its Impact on the Environment

Pyrolysis technology has diverse applications that significantly benefit the environment. By converting organic waste into energy, it reduces the volume of trash in landfills. This not only lessens pollution but also mitigates greenhouse gas emissions.

In addition to managing municipal solid waste, pyrolysis can process industrial byproducts like rubber and plastics. These materials often take centuries to decompose. Pyrolysis transforms them into valuable resources such as oil and carbon black, promoting a circular economy.

Moreover, this technology contributes to cleaner energy production. The bio-oil generated through pyrolysis can serve as an alternative fuel source for various industries. Businesses adopting pyrolysis machines demonstrate their commitment to sustainability while enhancing their operational efficiency.

The environmental impact is profound; with reduced reliance on fossil fuels and minimized landfill use, communities are moving toward greener practices that support ecological balance and resource conservation.

Cost and Return on Investment for Installing a Pyrolysis Machine

Investing in a pyrolysis machine can seem daunting at first. However, the potential for significant returns often outweighs initial costs.

The installation of this automation equipment requires careful financial planning. Costs may vary based on capacity and technology but generally range from tens to hundreds of thousands of dollars.

However, consider the long-term savings on waste disposal fees and environmental compliance costs. Businesses can also benefit from producing renewable energy or biofuels, which opens up new revenue streams.

Many companies witness payback periods between three to five years, depending on operational efficiency and local demand for energy products. Thus, calculating projected profits alongside expenses is crucial before making a decision.

Understanding the economic landscape is essential as market conditions fluctuate over time. This ensures that businesses make informed choices about their investment in pyrolysis technology.

FQAs

Many people have questions about pyrolysis machines and their functionality. Understanding these devices can feel overwhelming at first.

One common query revolves around the efficiency of energy conversion. How much waste does a pyrolysis machine need to process for optimal energy output? The answer varies depending on the technology used and the type of waste material.

Another frequent concern is regarding safety measures. Are there risks involved in operating such equipment? Manufacturers often include advanced safety features, but proper training is essential for operators.

Maintenance also raises eyebrows. What kind of upkeep do these machines require to function effectively? Regular checks and cleaning are crucial yet straightforward tasks that keep operations smooth.

Potential buyers often wonder about initial costs versus long-term savings. Is investing in a pyrolysis machine worth it over time? Evaluating local regulations can help determine this aspect effectively.

Conclusion: A Sustainable Solution for Waste Management

The pyrolysis machine represents a revolutionary approach to waste management, converting various types of waste into valuable energy while minimizing environmental impact. This technology not only addresses the pressing issue of waste disposal but also contributes significantly to energy production.

As society continues to grapple with increasing amounts of waste and dwindling natural resources, adopting pyrolysis systems can pave the way for sustainable practices. These machines efficiently transform plastic, rubber, biomass, and other organic materials through a sophisticated thermal decomposition process. The result is an array of products including bio-oil, syngas, and char—all useful in different applications such as power generation or even in manufacturing processes.

Investing in automation equipment like pyrolysis machines not only supports eco-friendly initiatives but also presents economic opportunities. With potential cost savings on landfill fees and the ability to generate revenue from byproducts, businesses are increasingly recognizing the value these systems offer.

As awareness grows around climate change and resource scarcity, solutions such as pyrolysis become vital. They address both environmental concerns and economic needs simultaneously—a win-win for communities looking toward a greener future. Embracing this technology could be key to transforming how we manage waste while fostering sustainability at every level.